Steel sheet and plate are basic products in a large range of sectors, notably in building, production, and manufacture. The difference in between both largely exists in their thickness and the applications for which they are suited. Steel sheets usually vary in density from 1/16 inch to 3/16 inch, while steel plates incorporate thicker products varying from 3/16 inch to numerous inches thick. The convenience of steel sheets and plates makes them integral components in the production of everything from structural frameworks and automobile parts to shipbuilding and machinery elements. Comprehending the buildings, kinds, and applications of steel sheets and plates is crucial for engineers, architects, and producers who depend upon these products for their tasks.

One of the most usual types of steel sheets is hot-rolled steel, which is created by rolling steel at high temperatures, making it easier to develop and shape. In addition, there are specialized steel sheets, such as galvanized steel, covered with a layer of zinc to supply enhanced deterioration resistance, making it appropriate for outdoor applications, consisting of roof and exterior siding.

Steel layers come in various qualities, including architectural, marine, and abrasion-resistant, each with details residential properties tailored for various atmospheres and loads. The choice of the ideal quality and type of steel sheet or plate is critical for making sure the security, performance, and durability of the last product.

The manufacturing of steel sheets and plates includes substantial procedures including cutting, bending, welding, and ending up. Welding is an additional important procedure in the setting up of steel frameworks, requiring understanding of various welding strategies such as MIG, TIG, and stick welding. The finishing process may consist of surface area therapies and coatings that improve the product's resistance to corrosion, improve looks, and lengthen service life.

The usage of steel sheets and plates has actually advanced with advances in technology, leading to innovations such as high-strength low-alloy steels, which provide equal mechanical properties to conventional grades while reducing weight. The continual research and growth in the metallurgy of steel are concentrated on producing lighter, stronger, and much more corrosion-resistant materials, which will further expand the versatility and applications of steel sheets and plates in various industries.

Sustainability is an increasingly important factor to consider in the manufacturing and usage of steel sheets and plates. Steel recycling has actually been an important component of the market for years, and the majority of new steel produced originates from recycled products. This procedure considerably decreases the carbon footprint associated with steel manufacturing, aiding to attend to environmental issues. Furthermore, manufacturers are taking actions to maximize their procedures, decreasing waste and energy intake, aligning with international sustainability objectives. The ability to generate top notch steel while lessening environmental influence not just benefits the planet yet additionally improves the reputation of firms devoted to lasting methods.

Steel plates offer as crucial elements in bridge building and construction, with designers designing steel plate girders to sustain heavy lots and period long ranges. Furthermore, steel sheets are thoroughly utilized in putting up steel structures, supplying flexibility in style while ensuring compliance with structure codes and safety requirements.

In the production sector, steel sheets and plates develop the foundation of a significant variety of items. From appliances to cars, the need for durable and trustworthy materials is vital. Automotive manufacturers use high-strength steel sheets to generate body panels that are lightweight yet unbelievably resilient, which adds to boosted fuel effectiveness without sacrificing security. In a similar way, the appliance market advantages from cold-rolled sheets with enhanced surface area coatings, guaranteeing visual allure while providing resilient sturdiness versus everyday deterioration. The assimilation of steel sheets in tools and machinery not only enhances the performance of items however additionally expands their lifecycle, providing significant worth to manufacturers and consumers alike.

On an extra customized note, the oil and gas sector's need for steel plates is driven by the building and construction of pipes and storage space centers that have to sustain severe atmospheres and stress. Steel plates utilized in these applications are commonly made to exacting criteria, guaranteeing they can stand up to the roughness of transportation and storage of diverse substances, consisting of unrefined oil and all-natural gas.

Past industrial applications, the aesthetic utilization of steel sheets has found a home in building layout. Modern style welcomes modern technology and technology, including steel sheets not just for architectural stability however for visual impact. Steel can be manipulated to develop vibrant exteriors, roof, and interior decoration components that commemorate the product's commercial heritage while using contemporary aesthetic appeals. Making use of corten steel, known for its rustic patina, is specifically preferred in producing outside sculptures and building facades that mix right into natural environments, showcasing the convenience and elegance of steel in numerous style viewpoints.

A number of elements have to be taken into consideration to ensure your projects continue efficiently when it comes to choosing suppliers for steel sheets and plates. The track record of the provider, product variety, quality control processes, lead times, and consumer service are essential components in choosing a companion. Lots of fabricators additionally need specific qualifications, such as ISO 9001, to guarantee that suppliers fulfill worldwide quality monitoring requirements. Furthermore, the schedule of value-added services, such as pre-fabrication and more info machining, can improve task timelines, supplying added value to makers and contractors.

As we look toward the future, the function of steel sheets and plates will likely pivot in response to emerging innovations and products science. The general pattern towards modular construction is likely to additional emphasize the significance of steel sheets and plates, as standard parts create effectiveness in setting up and lower on-site construction time.

In verdict, steel sheets and plates are necessary products that develop the foundation for numerous applications across a varied array of markets. As markets strive for innovation and ecological duty, the relevance of understanding and choosing the suitable steel sheets and plates will remain pivotal to attaining useful, economical, and sustainable engineering solutions.

Jonathan Taylor Thomas Then & Now!

Jonathan Taylor Thomas Then & Now! Tony Danza Then & Now!

Tony Danza Then & Now! Andrea Barber Then & Now!

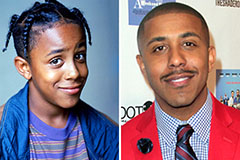

Andrea Barber Then & Now! Marques Houston Then & Now!

Marques Houston Then & Now! David Faustino Then & Now!

David Faustino Then & Now!